DIN 10524

Standard DIN 10524

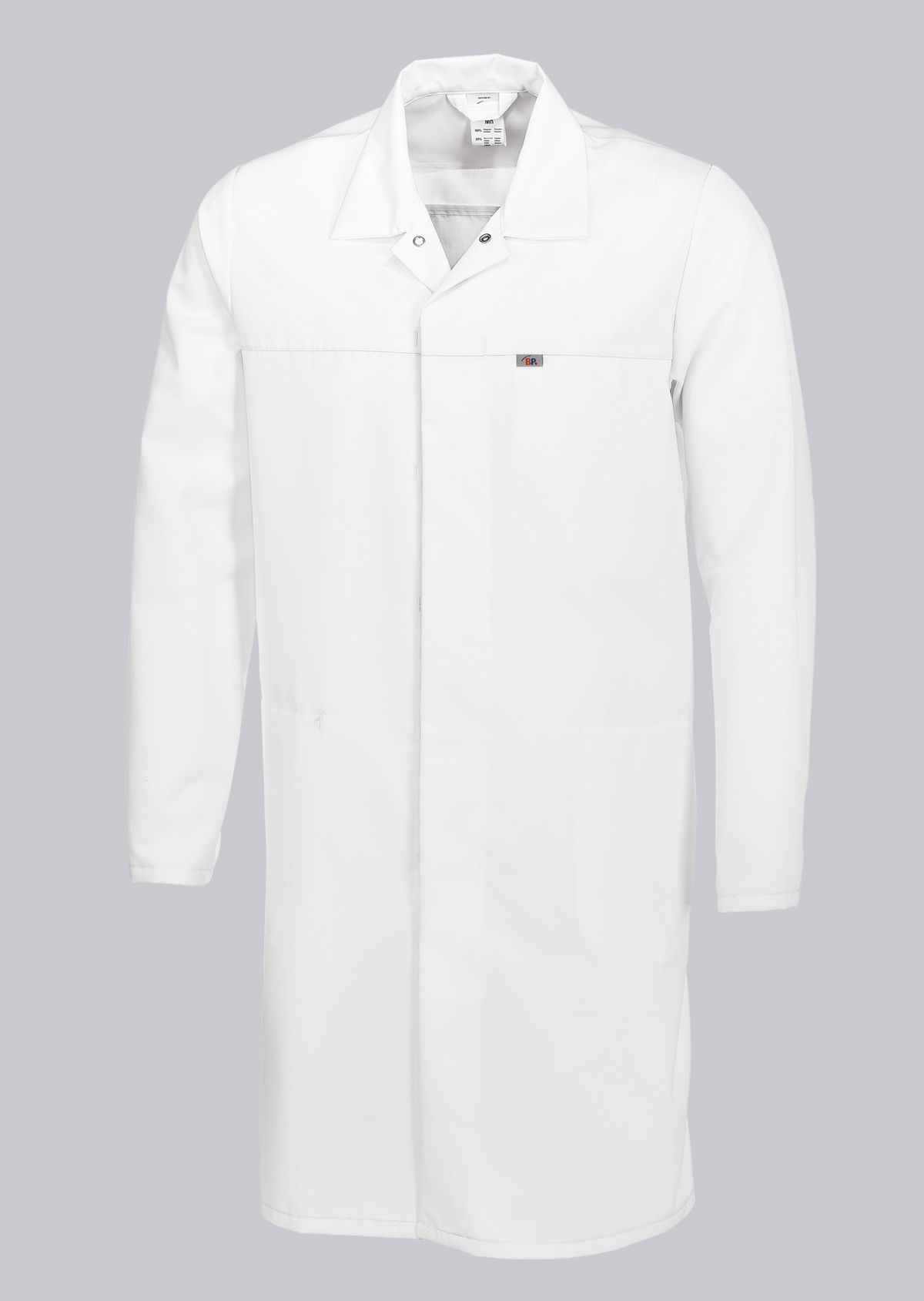

Food hygiene - Workwear in food businesses

In view of growing consumer demands and global trade networks, there was a need for a uniform standard to minimise the risk of contamination from inadequate workwear. Against this background, DIN 10524 was created, which is essential for food hygiene and workwear in food businesses. This is because it specifies the requirements for suitable and clean workwear.

The DIN 10524 standard not only contains hygiene requirements, but also provides recommendations for the selection, use and cleaning of clothing. The standard-compliant workwear is largely determined by the hygienic risk in the respective food production.

DIN 10524

Workwear for food companies

You want to equip an entire team or company with PPE and need support in selecting and compiling protective clothing that conforms to standards?

Get a quote

BP® NEWSLETTER

SPECIAL OFFERS, PROMOTIONS, NEW PRODUCTS AND MUCH MORE

Subscribe to our newsletter now and you'll be the first to receive all the information about sales promotions, new products or special online offers.

Subscribe to newsletter